CAD+T CNC

Optimize your production workflow by creating you CNC-data automatically. Whether interior designer, carpenter, joiner, shopfitter or exhibition stand designer this module enables fast and efficient data generation.

Share page:

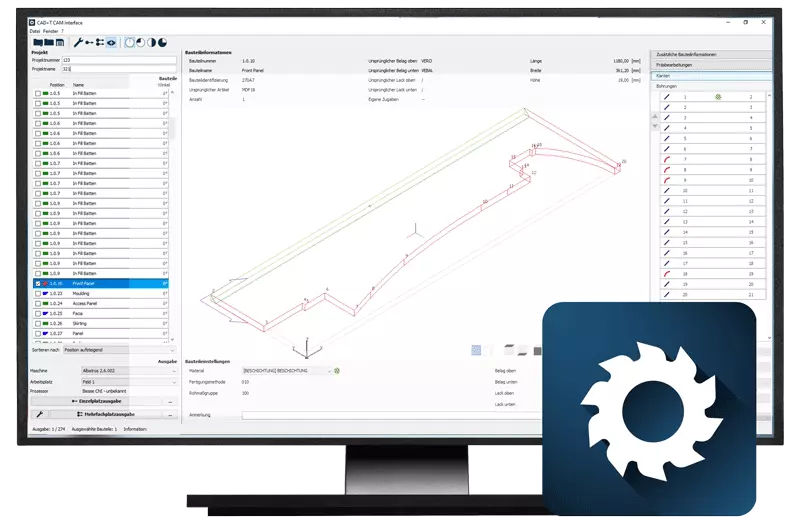

CAM Interface

The CAD+T CAM interface is an intelligent connection to 3-5 axis CNC machinery for the individual production. We generate directly out of CAD+T Engineer Classic or Professional module CNC-files which consider the geometry and material features of each part. The CAM system includes an intelligent work-on logic according to material, tools and production steps which increases the usage efficiency of the machine without the need of a specialized CAM-operator.

Your Benefit:

- High performance post-processor

- Logic based on material and geometry

- Also CAM silent mode available

- Simultaneous output for different CNC-machinery

- Automatic file recognition with barcode

- Definition of production steps

- Automatic tool selection

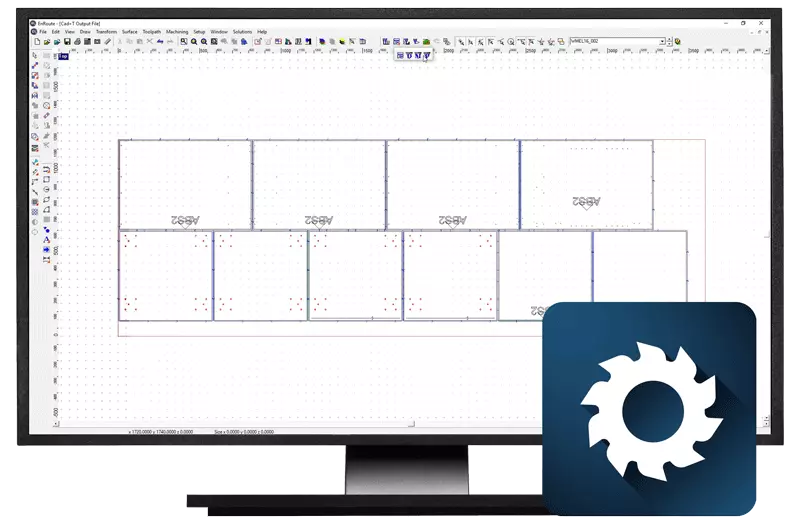

Nesting

Efficient nesting starts with the software and it ends at the finished part which leads to a faster and more efficient material handling in the workflow. Free shaped parts are placed by considering the tools and capabilities of the machine. We achieve through the perfect placement of small parts between the different sized parts an optimized material usage and save valuable resources.

Your Benefit:

- Intuitive user interface

- Output to nesting machine possible

- 64-bit engine

- Nesting with grain direction

- Combining and repeating orders

- Optimized production steps for wood based material

- Enhanced nesting for reduced material wastage

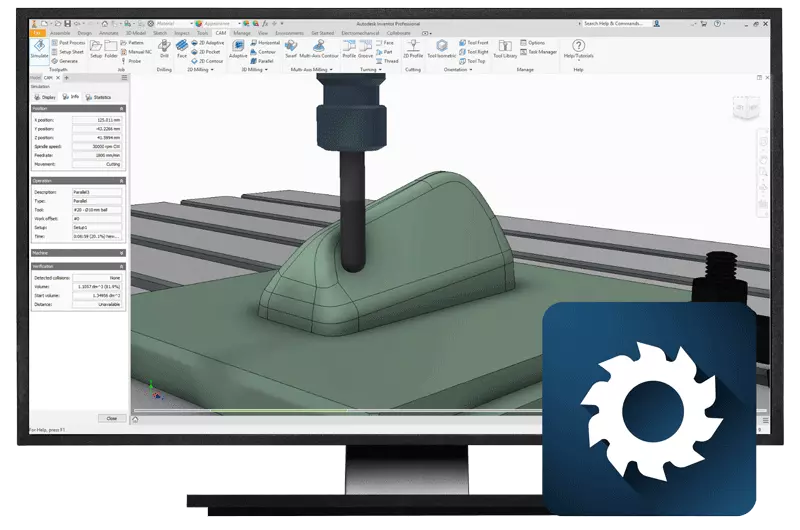

5-Axis simultaneously

Inventor® CAM is a 2,5 to 5 axis CAM system which allows 4 and 5 axis simultaneous work-on. The data is generated from CAD+T Engineer Professional, and through this high performance software, perfectly prepared for further production steps. You can check with the preview simulation for any potential collision. Additionally it will also calculate the time for more complex CNC programs. The Fusion 360 ultimate® is the cloud based solution for this.

Your Benefit:

- Complex 3D milling and 5 axis program simultaneously possible

- Analyze of volume bodies or flat surfaces

- Automatic takeover of 3D volume bodies

- Fast calculation and easy handling

- Vector drilling and milling

- Post-processor for several brands of machinery

- Adaptive clearing for optimal surface quality